Features & Benefits

- IDC contact provides a gas-tight connection to the PCB for long term reliability

- Plastic cap retains the contacts in position prior to automatic placement, then acts as the assembly tool to terminate the wires; no special tooling

- Tested to automotive levels on shock, vibration and temperature cycling for reliability

- Identical contact and footprint pattern to the existing 9175 for full backward compatibility and functionality

- The IDC contact reduces the total applied cost versus solder or crimp processes

- Connectors are available in two configurations for maximum flexibility; End and Through Wire

Typical Applications

- Connecting discrete wire components to a PCB

- Bringing power and signals onto a PCB

- Daisy chaining PCBs together to create a continuous string

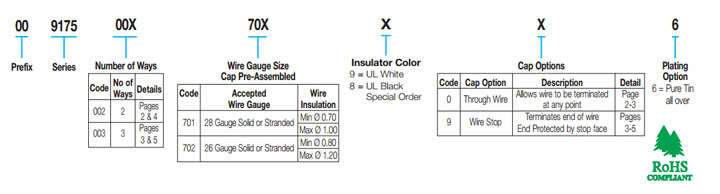

The market and applications for simple and reliable discrete Wire-to-Board connectors continue to evolve. Wexton Line first introduced the 9175 series of surface mountable Insulation Displacement Connectors (IDC) in 2006. Developed for harsh industrial and automotive applications, these connectors have been used in hundreds of applications from today’s “Smart Meter” all the way down to a simple sensor termination to a PCB. Size and performance has been one of the key factors for selecting this connector in terminating 26-28AWG wires to a PCB.

The next generation of IDC connector moves beyond all of the technical and performance attributes to address the “User Friendliness” of the product. By changing the insulator from acting as a connector body and make it more like a contact carrier, the insulator becomes the wire location and insertion aid without any special tools. The wire is just inserted into the cap (no stripping required) and then pressed down to provide a secure “Gas Tight” termination. This configuration simplifies and cost reduces the entire wire termination process for connecting discrete wires to a PCB.