Features & Benefits

- IDC contact provides a “gas tight” wire termination to the PCB to meet harsh industrial environments

- Simple, robust design offers a high performance solution to hand soldering large gauge wires to a PCB

- A single contact an handle up to 15A for high current applications with wire replacement up to 3 times

- The versatile family of IDC contact can accept 12-18AWG of stranded wires and can be tested for compliance with solid wires

Typical Applications

- Industrial pumps, motors and driver boards

- Solar and alternative energy products

- Commercial electrical equipment

- Reference Product Specification & application notes 201-01-141/142

Wexton Line developed the initial SMT discrete wire IDC connector 5 years ago for 26-28AWG Wexton Line wires. Since then, we have seen this Wire-to-Board (WTB) contact technology spread to multiple wire gauges and multiple configurations; standard connectors, capped connectors and single contacts. All of which addresses specific application or cost parameters set forth by our customer in demanding industrial, transportation or commercial applications. The heart of the IDC connector is the true “gas tight” WTB termination that is achieved once the wire is inserted between the dual phosphor bronze contact tines. These opposing tines provide enough spring characteristics to allow the termination to remain stable over extreme levels of temperature, shock and vibration.

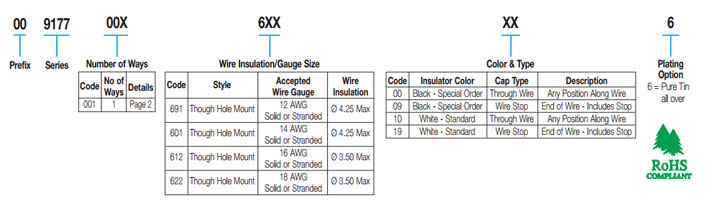

The new 9177-600 family of contacts incorporates all of the above mentioned capabilities. From low cost single contacts to fully integrated capped contacts. The unique feature of the 600 series is the fact that it was developed for Plated Through Hole (PTH) termination to the PCB. This addresses the rugged power type boards that have to handle larger wire gauges up to 12AWG and 15 Amps per contact of current. The PTH option provides robust PCB attachment and high current capabilities to replace older technology connectors or in most cases soldering stripped wires directly to the PCB.