Features & Benefits

- IDC contact provides a gas-tight connection to the PCB for long term reliability

- Plastic cap retains the contact in position prior to automatic placement, then acts as the assembly tool to terminate the wires; no special tooling

- Tested to automotive levels on shock, vibration and temperature cycling for reliability

- Identical contact and footprint pattern to the existing 9176 for full backward compatibility and functionality

- The IDC contact reduces the total applied cost versus solder or crimp processes

- Connectors are available in two configurations for maximum flexibility: End and Through Wire

Typical Applications

- Machine Controls: motors, drives, solenoids, sensors, fans and pumps

- Commercial Buildings: controls, security, fire and sensors

- Smart Grid: meters, breakers and panels

- SSL/LED: bulbs, fixtures, signage and streetlights

This single contact version of the proven 9176 family of connectors offers a lower cost solution to the market with only a 10% reduction in current rating. The SMT footprint is backward compatible with the standard dual contact configurations; offers all the same wire gauges and termination benefits of the integrated cap and provides a 10% height reduction.

Datasheet / Catalog – Click to Download

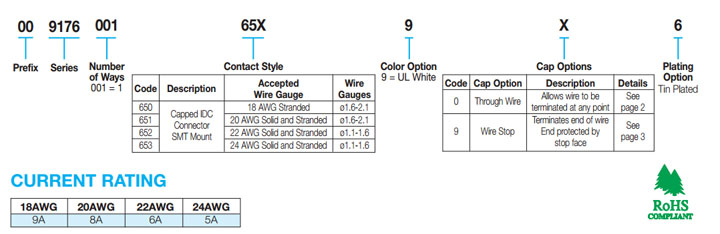

Part Number Information