Features & Benefits

- Non-burn safe technology

- Reliability level: 0.5%/1000 hrs.

- 6 case sizes available

- Environmentally friendly

- CV range: 4,7 – 1000µF / 1,8 – 10V

- IBM global approval received in 2004

- Elektra Award received in 2005

Typical Applications

- Automotive

- NB PCs

- Civil aircraft

- Industrial low voltage control circuits

NOJ OxiCap® capacitors use Niobium Oxide powder as the main material for the anode electrode for general applications. High reliability level (failure rate 0.5%/1000 hours); low ESR NOS devices have an even lower failure rate (0.2%/1000 hours) – even more reliable than tantalum capacitors. They are suitable for applications with rail voltages of up to 7V, such as in-cabin entertainment systems, seat position modules, airbag controls etc.

Niobium oxide has much higher ignition energy (200 times) and much lower burning rate than pure metal materials such as Tantalum or Niobium. This feature means that OxiCap® capacitors will not burn up to the category voltage. A further benefit concerns overload. A typical failure mode is high resistance (typically 20 to 200kΩ) after overloading by voltage spike or high current surge, which can result in increased leakage current and reduced capacitance. However, an OxiCap® capacitor will continue to provide full capacitance and functionality – albeit at the expense of increased power consumption. NOJ Series capacitors are designed as environmentally friendly and RoHS compliant product.

Datasheet / Catalogs – Click to Download

Technical Information – Click to Download

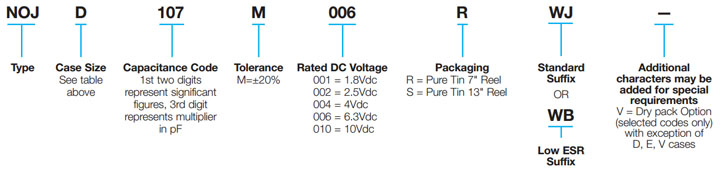

Part Number Information

Technical Papers – Click to Download

- Conductivity Mechanisms and Breakdown Characteristics of Niobium Oxide Capacitors

- Low Leakage Current Aspect of Designing with Tantalum and Niobium Oxide Capacitors

- New Tantalum Technologies: Tantalum Polymer and Niobium Oxide Capacitors

- Storage Capacitor Properties and Their Effect on Energy Harvester Performance

- Tantalum and Niobium Technology Roadmap

- Tantalum and OxiCap® Niobium Oxide Capacitors Deliver Enhanced Reliability, Wide Temperature Range, and Low Leakage for Automotive Applications

- Voltage Derating Rules for Solid Tantalum and Niobium Capacitors